Roto-Moulding Factory – Åndalsnes

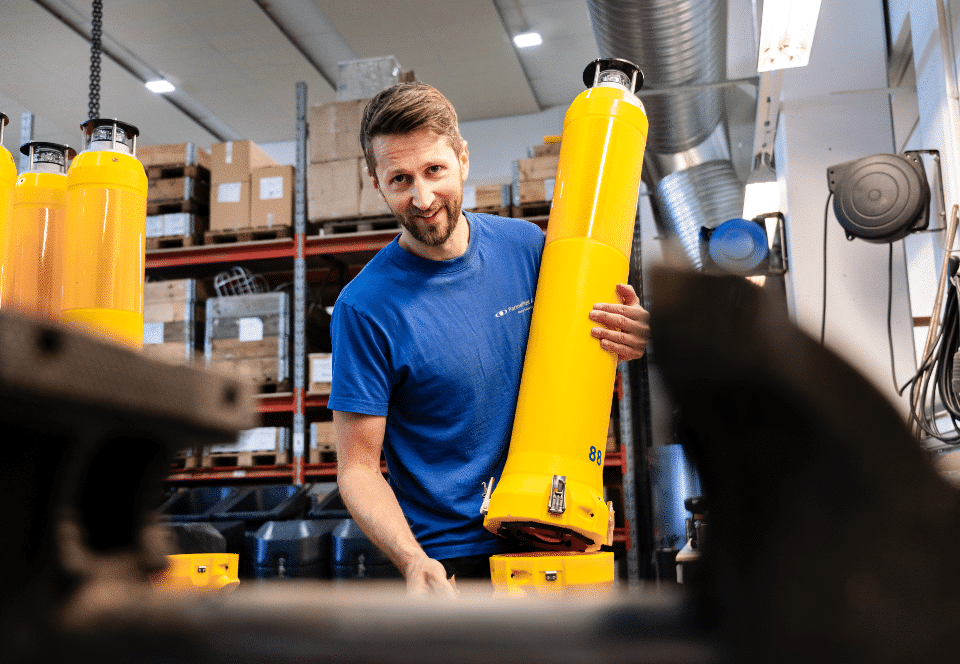

Our new manufacturing site opened in February 2017 and we have invested in a Rock & Roll oven for rotational moulding – one of the largest in Northern Europe. Our goal is to become the most efficient rotational moulding factory in Europe!

Click here to view the construction of the new factory as well as the installation of the latest machine for rotational moulding.

All our activity in Åndalsnes, Norway is now collated at one facility. Factory, administration and wharehouse are all housed under one roof. In total we currently have 5400sqm of offices and production space.

History and expansion

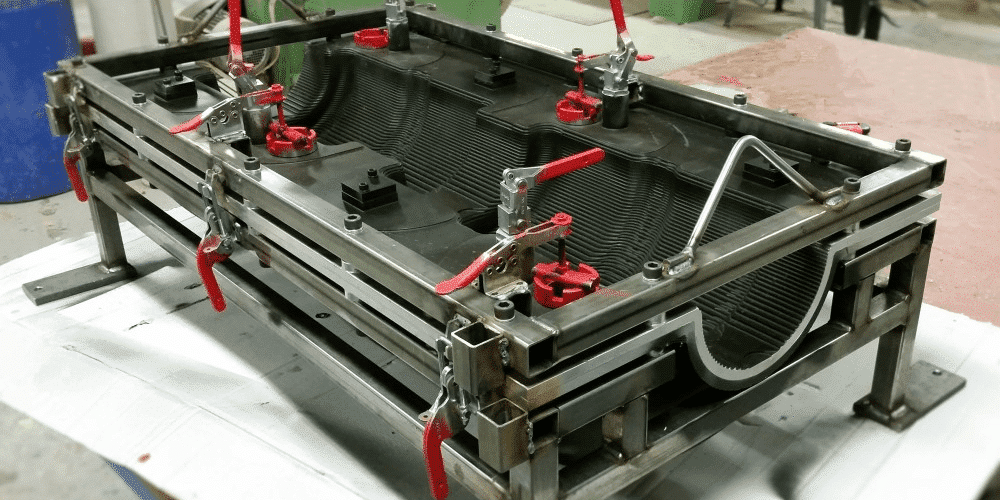

Construction of the Strandgata 3 factory started as early as 1957 and several expansions were subsequently made. The factory measured 3,500 sqm, and the location had an outdoor area of 10,000 sqm. All rotational casting was carried out in Strandgata, divided between five rotational casting machines. Since the start-up in 1992, the machine park has been expanded and modernised, and the latest addition was a rotational casting machine installed in 2017.

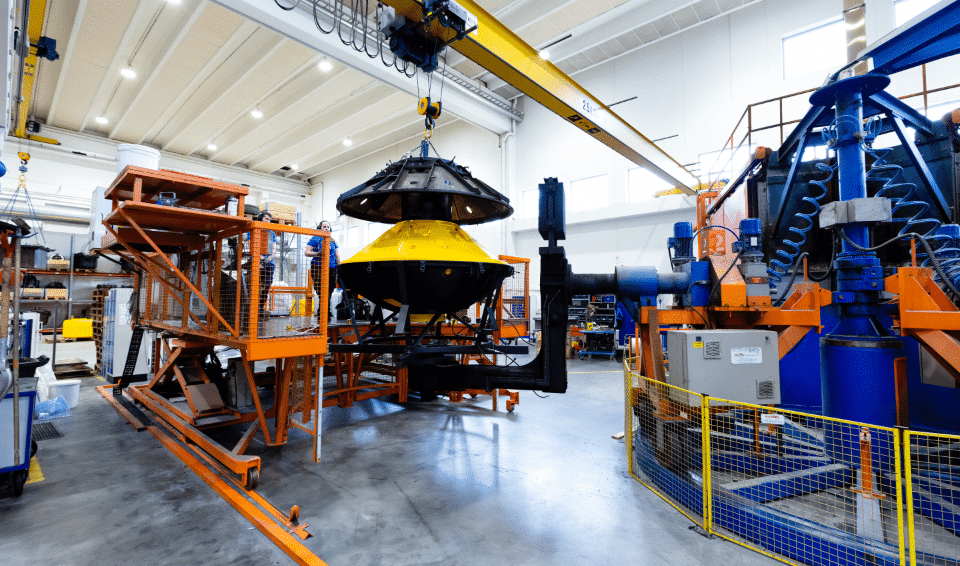

In addition to rotational casting, PartnerPlast also had a mechanical workshop where we manufactured our own moulds for rotational casting. PartnerPlast built a new factory at Øran Vest in 2007. The total floor space of this factory was 2000 sqm, and it had an outdoor space of approximately 23,000 sqm.

The factory was built to create more space for our Offshore & Subsea production and accommodates a modern and advanced machine park for this purpose. In addition to production facilities, the localation also contains the administration part of the Company.