Rotational Moulding

Rotational moulding is a production process that is particularly suitable for large, hollow products.

We can produce parts with uniform wall thickness and complex shapes, at a relatively low production cost.

The production method means that you get a homogeneous material with low tension and no welding seams.

Get in touch

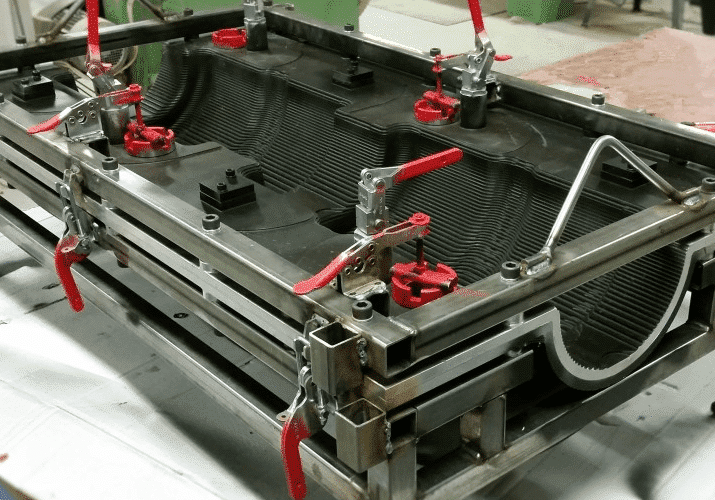

Rotational moulding process

Moulds are first filled with small plastic pellets. The mould is then heated and rotated with cetrifugal force to coat the inner walls with plastic evenly, creating stress-free, seamless parts. No additional pressure is required during the casting.

Additional processes can be added; for example filling with polyurethane foam or epoxy filler. Rotational moulding also offers the opportunity to manufacture stress-free parts with uniform wall thickness and complex shapes at a relatively low production cost.

Benefits of rotational moulding

Compared with traditional methods, rotational moulding supports large hollow parts, consistent quality and short changeovers. It’s well suited to marine and industrial environments where reliability and low maintenance are essential.

Materials

Medium and High Density Polyethylene (MDPE, HDPE) are the materials of choice for roto-moulding at Ovun. These materials are fantastically durable and versatile.

Ovun uses MDPE and HDPE for excellent impact strength, chemical resistance and long service life. Material selection is matched to each application to balance durability, weight and cost-efficiency.

Experience

We have a long history of development, innovative thinking and design in its various segments. Plastic products can be used in combination with components of steel and aluminium as well as integrated electronics systems.

Advantages

Low internal stresses

Rotational moulding

Relatively low tooling costs

No welding seams

Large products at low cost

Design freedom - realise your dream

Get in touch

Rotational moulding is a production method in which plastic powder is heated inside a mold that rotates around multiple axes. As the material melts, it distributes evenly along the walls of the mold, forming a seamless hollow product. Ovun AS uses this technique to manufacture customized components such as buoyancy elements, tanks, and various industrial products. The products can be adapted with additives that provide impact resistance and UV protection and typically have a lifespan of 15–30 years, depending on the application.