Patterns & moulds

Ovun Innlandet (formerly Molstad) is a modern tool and model manufacturer. We have key expertise in 3D scanning, reverse engineering, construction, foundry models, patterns and moulds, as well as advanced machining.

This combination of skills enables us to deliver precise and reliable solutions tailored to complex industrial needs.

Get in touch

Patterns & moulds

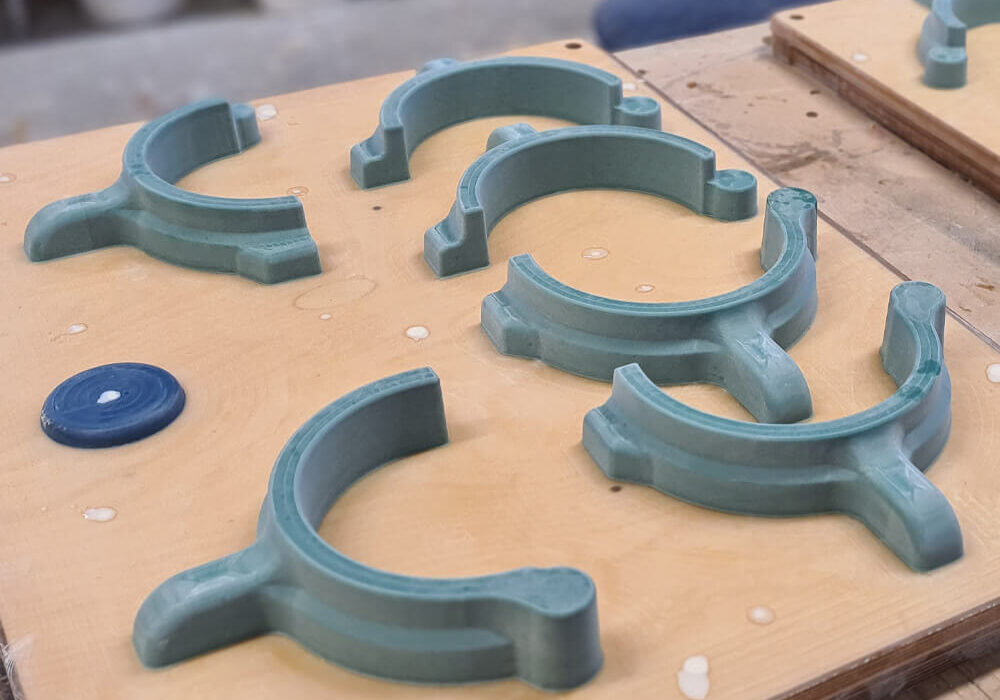

We develop and manufacture products in Polyurethane elastomers, and have expertise in the entire value chain from design and construction to the production of casting tools and casting products in a wide range of material qualities. This gives us the flexibility to tailor solutions for different industries and applications, from prototypes to large-scale production. In addition to PU- molded products, we also supply molded, machined and surface-treated products in aluminium, iron and steel, always adapted to demanding industrial needs where strength and durability are crucial.

As a competence center in 3D scanning, construction and milling services, we support customers throughout the development process. Our highly qualified constructors have extensive experience in product development, foundry models, and the design and production, ensuring precision and reliability from idea to finished product. By combining modern technology with decades of hands-on expertise, we help our customers reduce risk, improve efficiency and achieve solutions that perform reliably in practice

Experience

With more than 20 years of experience producing foundry patterns and moulds, casting tools and CNC machining, our competence is proven through consistently delivering the best solutions for our customers. Over the years we have built a strong network of leading suppliers and trusted partners in the industry, ensuring that every project benefits from high-quality materials, modern technology and reliable delivery.

Our long-standing expertise also gives us the ability to adapt quickly to new challenges, whether it involves complex geometries, demanding tolerance levels or the integration of different materials.

By combining craftsmanship with modern production techniques, we create patterns and moulds that not only meet, but often exceed customer requirements. This provides our customers with confidence that we will always deliver outstanding and lasting results.

With more than 20 years of experience producing foundry patterns, moulds, casting tools and CNC machining, our competence is proven through consistently delivering the best solutions for our customers.

Over the years we have built a strong network of leading suppliers and trusted partners in the industry, ensuring that every project benefits from high-quality materials, modern technology and reliable delivery. This gives our customers confidence that we will always deliver outstanding results.

Advantages

3D modelling

Patterns & moulds

Relatively low tooling costs

Casting patterns

Mould fabrication

Proven track record

FAQ

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Mauris bibendum lectus ac arcu suscipit vulputate. Nunc ullamcorper quam turpis, vitae molestie arcu faucibus vitae. Vestibulum ante ipsum primis in faucibus orci luctus et ultrices posuere cubilia curae; Donec euismod quis quam quis condimentum.